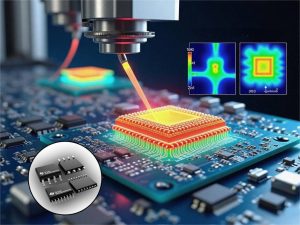

Visual comparison: SSOP 0.635mm vs SOIC 1.27mm lead pitch with JEDEC standardization markings

Choosing the right integrated circuit (IC) package is key in electronics design. Two common surface-mount options are SOIC and SSOP. They look similar but have important differences. These differences affect how they are used.

Understanding SOIC and SSOP Packages

SOIC and SSOP are both surface-mount packages (SMT). They have leads for direct soldering onto a PCB. SMT allows for smaller and denser electronic devices.

Key Distinctions Between SSOP and SOIC

Let’s explore the main differences between these two package types.

Nomenclature and Standards

“SOIC” is the more standard and widely accepted term. Datasheets and manufacturers often use it. It refers to a specific type of surface-mount package.

“SSOP” means “Shrink Small Outline Package.” It’s a smaller version of the SOIC. The “shrink” refers to its reduced overall size.

Lead Pitch (Pin Spacing)

The biggest difference is the lead pitch, the space between pins.

SOIC typically has a lead pitch of 1.27 mm (50 mils). This wider spacing makes manufacturing and PCB layout easier.

SSOP has a much finer lead pitch, usually 0.635 mm (25 mils). This tighter pitch allows more pins on a smaller package.

Package Body Size

SSOPs are generally more compact than SOICs with the same number of pins. The tighter lead spacing allows for this.

SOICs come in narrow (around 3.9 mm) and wide (around 7.5 mm) body widths.

SSOPs also have different widths. However, they are typically smaller than comparable SOICs.

Typical Applications

SOICs are used in many applications where space saving is important. Examples include logic ICs and op-amps in industrial and commercial devices.

SSOPs are designed for space-limited applications needing high component density. They are common in portable electronics and memory modules.

Why These Differences Matter

Understanding these distinctions is crucial for electronic design.

Saving Board Space

SSOPs allow for higher component density due to their smaller size and finer pitch. This is vital for compact electronics.

Manufacturing Considerations

The finer pitch of SSOPs can make manufacturing and soldering more difficult. Precise techniques are needed. SOICs are generally easier to handle.

Pin Count and Functionality

SSOPs can accommodate more pins in a smaller area. This is useful for complex ICs in limited space.

In Simple Terms

SOIC is a standard, easy-to-use surface-mount package. SSOP is a smaller, higher-density version. The main difference is the lead pitch and resulting size. Choose based on your space constraints and manufacturing capabilities.